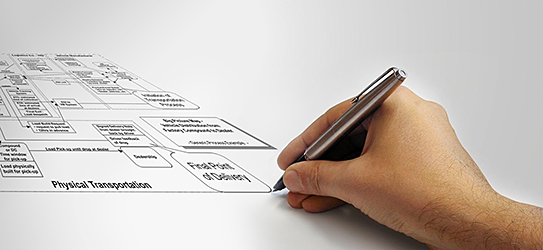

Value stream mapping is a

lean management principle, used to analyze and design the flow of

materials and information required to bring a product or service to

a consumer.

This map has to be considered the blueprint

of "the best in class manufacturing" you want to build.

It is important, prior to start with VSM, to define the Products Family.

Go to the details: What is Value Stream Map? >

There is a quite standard method to draw a value stream map and

there is a rigourous path to follow to be efficient in doing

it.

The value stream map is a useful tool because:

You can see the flow

You can speak a unique language worldwide (easy to

understand)

You can address the resources to the critical step of the

flow

You can see both the material flow and information flow

You can bring the map on the shopfloor and everybody can modify

it

Go to the Value Stream Map Road Map >

Even if the main pillar of Value Stream

Mapping is "Pen and Sheet", it could be useful (later) to put the

data in an VSM Software to do some calculation, store the map or

share it worldwide.

For these purposes LeanLab created a simple tool.

Download the Demo of LeanLab VSM Visual Factory >